However, when it comes to boatbuilding, a large dose of positive thinking is mandatory because of the profound leaps of faith needed to make progress on all but the simplest of projects.

The newbie boatbuilder discovers this as soon as he has to make the first cut into a valuable piece of wood. And even intermediate duffers, such as myself, run into it at practically every turn.

When I last left off, I was hesitating about cutting the hole for the drawer in my dish rack front, because I was afraid of destroying a piece of teak that Id put an awful lot of work into. However, in planning my drawer, I realized it would be easier to make the drawer fit the hole, than make the hole fit the drawer. Safer, anyway. I could always throw away the drawer if it didnt fit the hole.

Armed with this insight, I gathered my courage, and took the leap, cutting the simple rectangular slot for the drawer. I did this by drilling a hole in the teak, and then using my saber saw to cut out the slot.

|

| Cutting out slot in front for drawer |

Its not. It should actually be about a half-inch taller. I dont know what I was thinking.

Anyway, better too small than too big. I quickly enlarged the hole to the correct size.

|

| Add caption |

Yes, I really do talk that way when Im on my own. Heres the video, which I highly recommend.

So, I ordered the dovetail bit (Freud 22-112 1/2-Inch Diameter 14-Degree Dovetail Router Bit with 1/2-Inch Shank

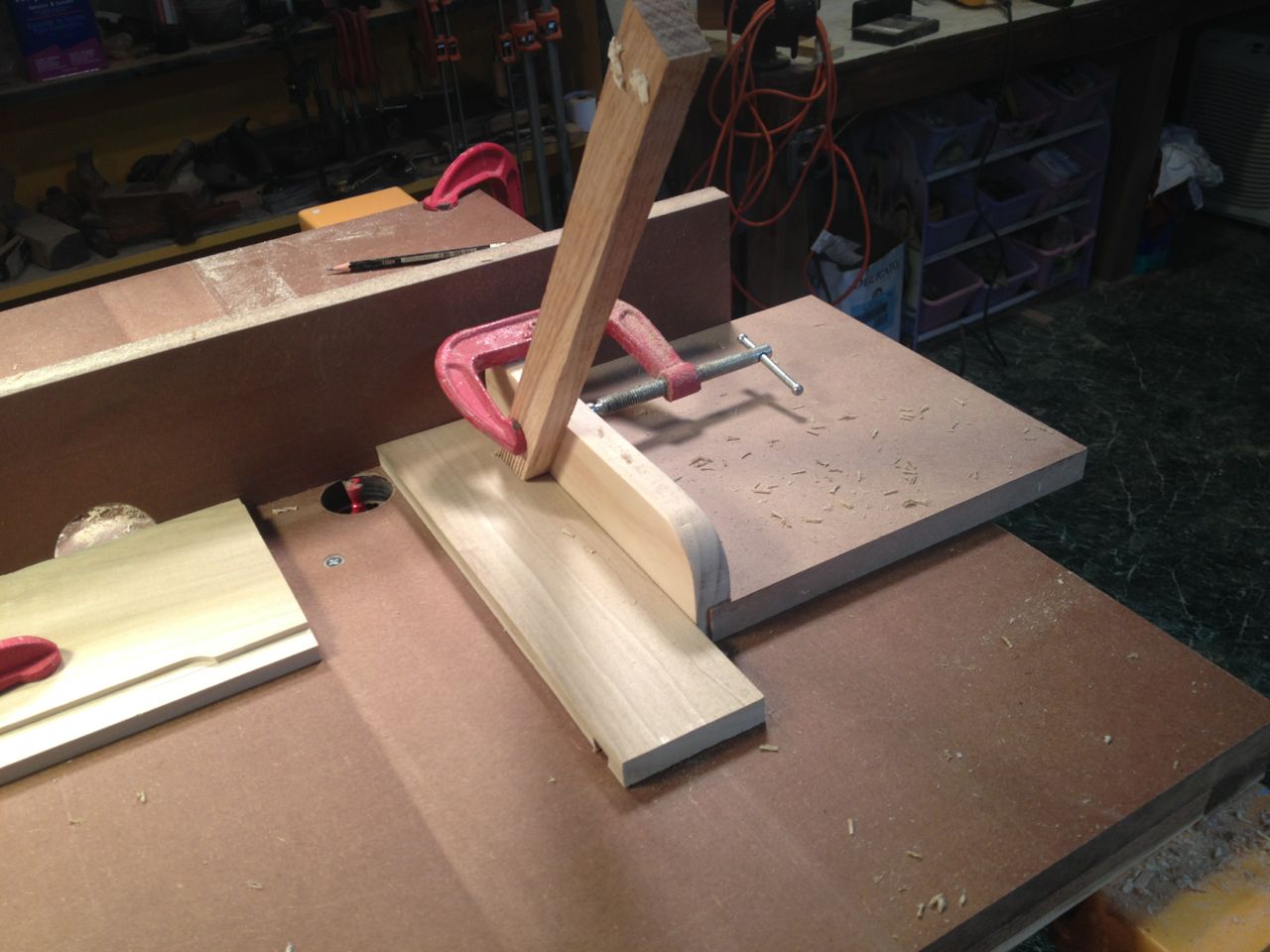

This is the setup I ended up using:

|

| Cutting blind dovetails in front of drawer |

It was actually pretty easy to cut both the dovetail slots and tails in the poplar, which is a softwood and fairly easy to work with. But I wanted the drawer front to be made out of teak to match the rest of the rack. Thats where the trouble started.

|

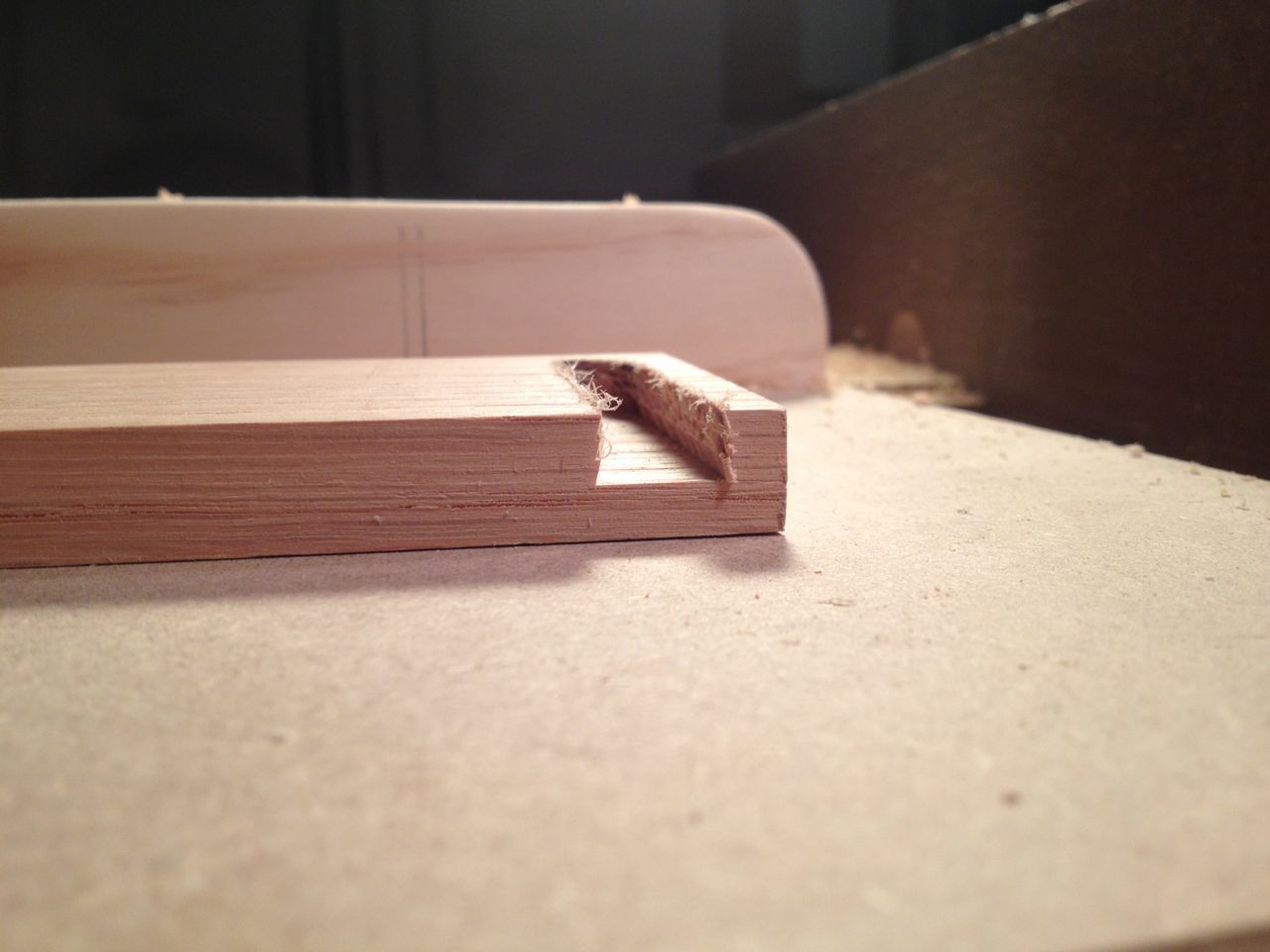

| Sliding dovetails in drawer body. |

No matter what I did, Id get a massive chip-out in the drawer front when cutting the slot. Heres the nice piece of teak I wanted to use:

|

| Chip out when cutting slot in hardwood |

"Surely," I thought in my most positive manner. "Surely it is possible to cut this slot if I just go a little slower."

Bzzzzzzzz pop!

"Blast. Maybe if I go a little faster..."

Bzzzzzzz pop!

"I know! I need to hold it down better. Let me clamp this feather board over it, so its nice and tight against the router table. That will do it!"

Bzzzzzz pop!

"Double blast! Well, maybe I can try..."

Applying that sort of positive thinking over and over again, I eventually experimented that piece of teak out of existence. Nothing, positively nothing, worked.

So, I decided teak was out and oak was just the thing for the drawer front.

Bzzzzzzz pop!

Same thing.

"Ah, ha!" I said, suddenly struck by a bolt of cleverness. "I know what to do, Ill just cut the slot a bit at a time. In two, no, three steps! No way it will split out then."

Bzzzzz. No split. Bzzzzz. No split. Now, for the final depth... Bzzzzz. No split!!!

Oh. Rats.

|

| Why you cant cut a dovetail slot in three steps. |

Thats when I realized that poplar -- yes, that beautiful green softwood -- would make the perfect drawer front.

|

| Draw glued together |

|

| A perfect fit |

|

| If you click on the photo above, you can see the lock slot in the bottom of the drawer. |

I decided to varnish the whole rack, and paint the drawer. Ill match the color of the drawer to the color of the galley (a flavor of warm white). With a bronze handle, the drawer should look pretty good.

Heres the rack, bottom, and drawer with sealer/primer applied. Hope to have it installed by the weekend.

If you have any idea how to cut a dovetail slot into hardwood without chipping out the end, please (please!) add it to the comments below.

|

| Why doesnt everyone varnish everything? One of the great mysteries of life... |

Next Episode: Here we go again

Subscribe to:

Post Comments (Atom)

0 comments:

Post a Comment